Materials & Services

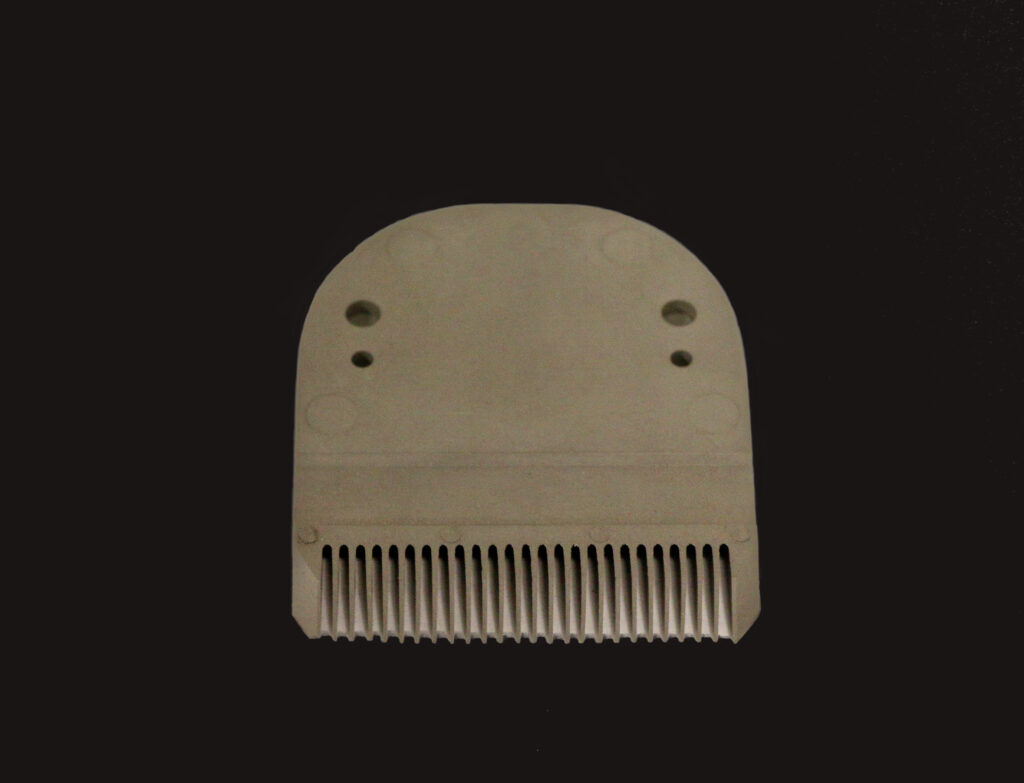

Feedstock, a highly engineered mixture of metal powders and organic binder, is the raw material used to produce complex parts with injection molding, a process commonly used with metals and plastics.

AMP’s engineered feedstocks are precisely formulated, compounded and pelletized to give you guaranteed consistent batch-to-batch performance. Our deliveries are coordinated to meet your specific production demand and schedule.

You can expect:

AMP offers a broad portfolio of standard and specialized feedstock materials for our customers’ wide range of applications. We will work with you to create custom-tailored formulas optimized to get the best results from your processes.

ADVAMET® Wax Polymer Binder System

ADVAMET® feedstock uses AMP’s pioneering proprietary wax polymer binding system. It is the first of its kind in the world and offering s excellent operating performance and superior molding characteristics.

ADVACAT® Catalytic Debinder System

ADVACAT® feedstock uses AMP’s catalytic (POM) catalytic binder system and offers superior dimensional control.

ADVATOLL™

Toll Processors for Your Formulations

ADVATOLL™ is a process that creates compounding and pelletized MIM feedstock formulations, creating custom lot sizes from 5lbs (2.5kg) to 1,700lbs (800kgs).

AMP is ISO 9001 certified and has the processes, dedicated equipment, expertise, materials knowledge and testing facilities to ensure that each lot of material consistently meets specification every time.

ADVARENEW™

Restores Overworked Feedstock

ADVARENEW™ is a process service that restores overworked feedstock to its original rheology. MIM feedstock rheology can change significantly after multiple processing and regrind cycles. Using our in-house testing equipment and expertise, AMP characterizes the feedstock’s rheological data and rejuvenates the binder system. Our final quality assurance checks, including MFI and capillary rheometer testing, confirm that the renewed materials’ viscosity and MSF characteristics are restored.

AMP strives to continuously improve the quality and reliability of the products and services we offer our customers.

The quality of our feedstock is directly related to our meticulous batch-processing technique. Raw materials are mixed in-house and weighed precisely in order to better achieve the proper ratio of metal powder to polymer binder.

Our production team, investment in R&D, and ISO 9001:2015 certified facility and processes ensure that our feedstock meets your stringent specifications and delivers the performance you expect.

AMP serves customers throughout many industries and with a wide range of product applications. If you don’t see your industry or product application below, contact us to discuss the potential of working with AMP.

Advanced Metalworking Practices serves customers in metal injection molding and related industries throughout the US and the world by providing superior quality MIM feedstock products and services, and prioritizing constant improvement and innovation.

© Advanced Metalworking Practices 2024. All rights reserved

Powered by JDR Web Solutions